Do we really know what’s the safety footwear made of? Today we’ll explore one for you.

All the footwear pieces are quite similar in between themselves, doesn’t matter if we are talking about boots, running shaped or sneakers.

There are some visible pieces that are quite evident to human’s eye but we rarely know what are they designed for.

Inside this post, we’ll talk about each element, one by one from the smallest one to finally build a complete safety shoe.

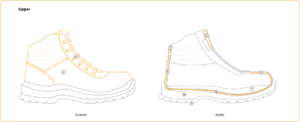

Let’s begin with the upper área. Where we’ll find:

Toe cap.1

There are several kinds for every different purpose, however all of them should be cappable to resist 200 J drop impacts and 15KN under compression in a static pressure test. Different materials such as Steel, Fiber glass, alluminum…

Upper.2

Apart from the different kind of leathers, we can find a huge variety of synthetic or textile materials. Each one has its own properties and so if we combine them we obtain great characteristics from this compound materials such as water resistance, non slip, better price, bacteria free…

Linning.3

This material is directly in contact with our foot, so it should pass all the vapour permeability tests, perspirability tests, it should dry quickly, and it should be abrasion resistant

Moreover it should be confy and could be made of leather, textiles, membranes…

Heel cap.4

In order to offer the best posible protection against going over on the ankle and to give a pleasant fit, the back of the shoe features what is known as a heel cap. This can be made from cardboard on the basic styles and then up to leather, thermoplastic foil or thermoplastic rubber depending on the range and Price.

Padding.5

Due to the abrasion produced by our foot when walking, pieces such as the tongue or the collar should be soft and confy. If not, it could seriously hurt our feet. This padding not only helps with the confort, it also allows the laces to spread out the pressure and giving the user a better adjustment feeling.

Laces.6

This piece is very important, it allows us to seal or adjust the shoe to our foot. Thanks to a huge variety of bows, we can get different results, avoiding some specific pain, adjust the same shoe to different kind of foot.

We’ll talk about this specific piece of the shoes in future posts.

Confort footbed.7

Can have different designs depending on each feet or diseases such as flat foot, high arched foot…

Furthermore they should be breathable as well as be able to dry quickly.

Anti penetration insole.8

The main purpose of this insole is to protect the foot sole against any fear that could be able to bore into the boot. They should be able to resist 1.100 N.

We can find safety insoles made of steel; metallic or non metallic made of different fibers (commonly known as kevlar insoles).

This antipenetration insoles cannot be taken off the shoe, as opposed to the confort footbeds.

Footwear soles are usually made of 2 different areas, the outsole (in contact with the ground) and the midsole (the softer area above the outsole).

Outsole.9

Can be made of TPU (Thermoplastic Poliuretane), rubber and poliuretane.

Each material have different features, for example, poliuretane its a great shock absorver as well as lighter than the rubber, which is a great heat and chemical resistant material.

Midsole. 10

It is the softest part of the sole, it means its a great shock absorver, light and definitely its the area that provides us the confort.

It can be made of different materials such as EVA, lower density Poliuretane…

Leave a Reply